1、Project name: Operation and Maintenance Cloud Platform for Facilities and Equipment of Shenzhen Institute of Advanced Technology Chinese Academy of Sciences

2、Project address: Shenzhen City, Guangdong Province, China

3、Project overview

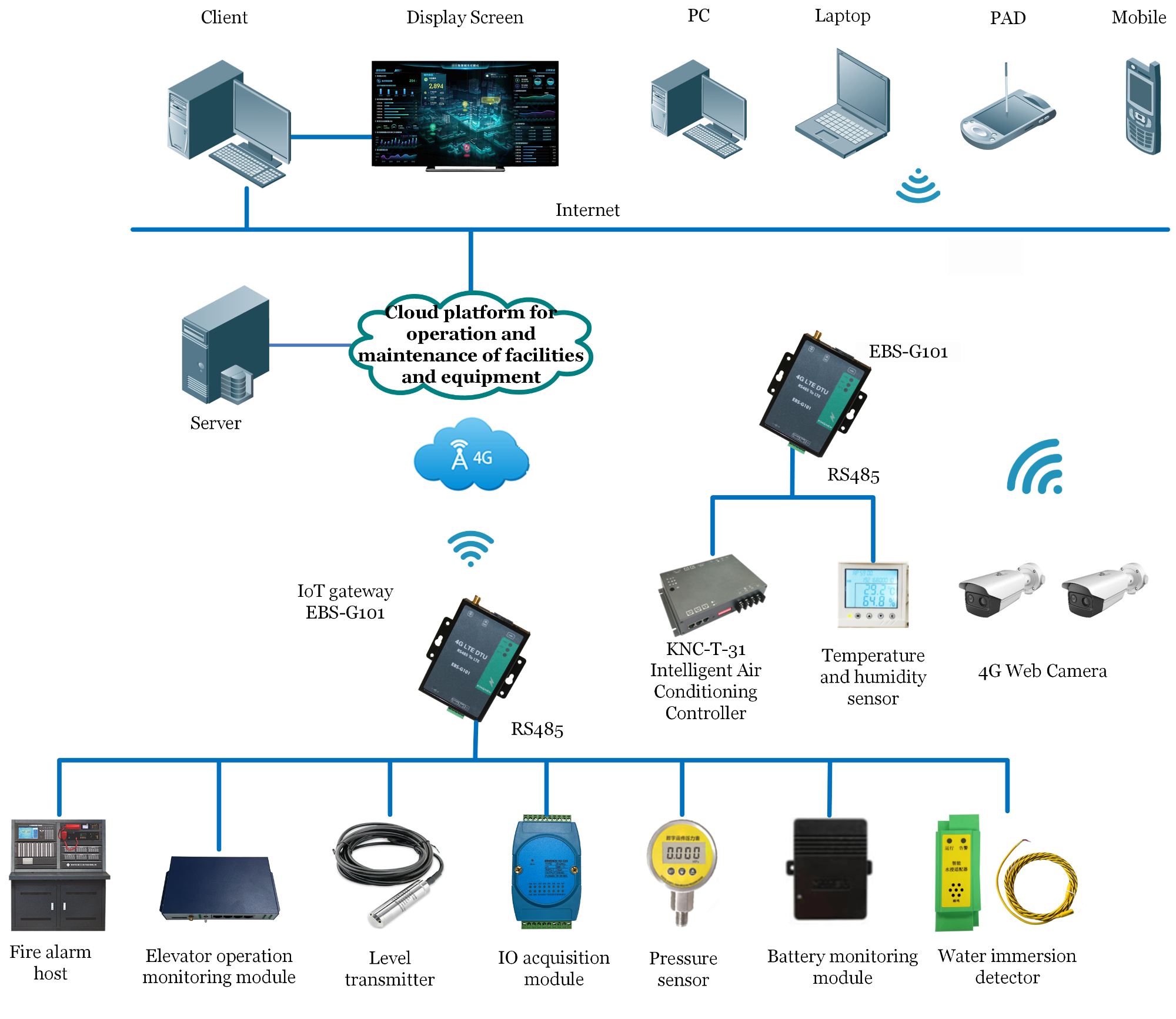

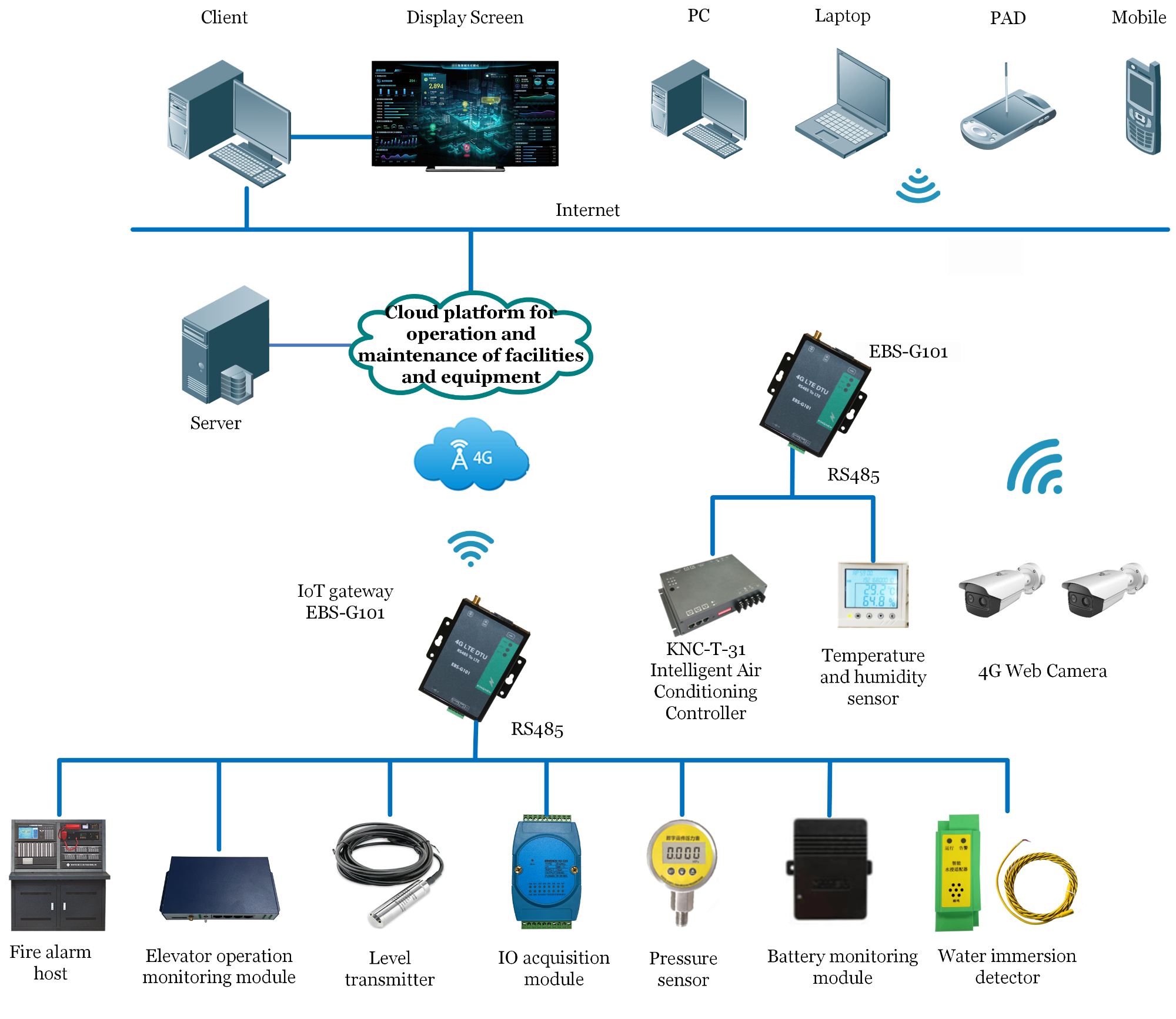

The cloud platform for operation and maintenance of building facilities and equipment includes the monitoring and control of energy consumption and working conditions of central air conditioning, power supply and distribution, water supply and drainage, fire protection systems, elevators, lighting and other facilities and equipment. The monitoring and transmission of the Internet of Things is realized through the hardware and sensors of the Internet of Things, and the data is collected in real time and transmitted to our cloud platform to achieve online monitoring and dynamic analysis of energy consumption and equipment status. Access and display through PC and mobile APP.

This project is a facility operation and maintenance project of Shenzhen University of Technology, Chinese Academy of Sciences. It mainly monitors the low-voltage power distribution room, diesel generator room, domestic water pump room, fire linkage control system and elevator machine room of Building D. Install equipment in the machine room and upload the collected real-time data to the facilities and equipment operation and maintenance cloud platform to achieve online supervision and improve the operation and maintenance efficiency.

4、Project scope

Main monitoring contents:

1、 Low voltage distribution room of building D

- Collect on-site video monitoring data through 4G webcam. Webcams are installed in important machine rooms to monitor the operation of equipment rooms, transmit images of equipment rooms in real time, and monitor the real-time status of equipment rooms. Through the means of "online supervision+offline maintenance", the full life cycle management of important equipment is realized.

- An intelligent controller is added to the split air conditioner in the machine room to realize remote switch on, operation mode adjustment, remote temperature setting and power metering.

2、 Diesel generator room of building D

- Monitor the internal resistance, temperature, electricity quantity of the battery in the machine room, and the temperature and humidity detection, water immersion and other non electrical parameters in the machine room to achieve real-time monitoring, so as to ensure the stable operation of the machine room.

3、 Domestic water pump room

- Collect the water level of the fire pool/sump, the pressure of the water pump pipeline, install the status collection system, and master the operation status of the control cabinet in the water pump room in real time to help the operation and maintenance personnel quickly find and deal with the problems in the operation of the equipment, improve the operation and maintenance management level of the water pump room equipment, and ensure the normal domestic water.

4、 Fire linkage control system

- Collect the alarm information from the fire alarm host and upload it to the cloud platform to push the alarm information to relevant personnel in time.

5、 Elevator machine room

- Install temperature and humidity sensors and water immersion sensors in the elevator machine room to monitor the environment of the machine room and ensure the safe operation of the elevator.

- For the elevator car, the elevator safety operation monitoring terminal is added to monitor the status of the elevator, such as up and down, stop, floor, trapped people, card floor, overspeed, speed, left and right swing, up and down vibration, temperature and humidity.

- Monitor the water immersion of the elevator pit to prevent damage to the elevator equipment due to the water immersion of the elevator pit.

5、Network diagram

6、Field installation pictures

6、Field installation pictures

Elevator operation safety Pipeline pressure

Intelligent air conditioning controller

7、Customer revenue

The enterprise realizes the real-time monitoring of pipeline temperature and pressure through the construction and implementation of equipment management platform, replacing the complexity of manual statistical work, and establishes the equipment operation status database as the data analysis basis of the facilities and equipment system.

The facilities and equipment system not only helps the whole enterprise realize real-time understanding of equipment operation and improve management, but also brings huge economic and social benefits. It is mainly reflected in the following aspects:

- Fast business abstraction enables all the businesses in the existing platform to be supervised.

- Under the perfect business functions, it realizes business supervision, provides perfect query of various business reports, and the headquarters conducts real-time control.

- Establish equipment and facilities account, realize digital account management, open up online business chain, connect all data, supervise front-line employees' work, and track operation status in real time, so as to build a scientific, strict, efficient and practical facility and equipment management information management platform.

- Through seamless connection between facilities and equipment management system and relevant management systems, facilities and equipment managers can fully handle daily work through the facilities and equipment system, providing one-stop service for facilities and equipment managers.

- Get through the whole online business chain, ensure that the daily work of front-line employees can be realized online, leave no business blind spots, and make front-line operations simple, standardized, and supervised.The automatic data collection mode replaces the traditional manual mode to optimize the equipment operation and use. Find out abnormal conditions of equipment operation through monitoring, and then optimize equipment, improve equipment performance, extend equipment service life, improve management efficiency and reduce maintenance costs.

- Integrate data collection, transmission, analysis and other information technologies to achieve information transmission from the site to the cloud, and from the cloud to the WEB. Through data analysis, timely find out the abnormal conditions of important equipment, timely remind management personnel to take countermeasures to reduce the occurrence of emergencies, and eliminate the blind area of manual operation and maintenance.

6、Field installation pictures

6、Field installation pictures